“The Indian Automotive Manufacturing Industry is the fourth-largest in the world by production, employs over 10 million people and contributes 7.1% to India’s GDP(2022) and 49% of the country’s manufacturing GDP.”

The Automotive Manufacturing industry is on the verge of a remarkable transformation. With the emergence of new technologies and materials, the way cars are made is being redefined. In the not-so-distant future, we’ll be cruising around in vehicles that are lighter, more efficient, and environmentally sustainable. This article explores the key advancements in materials and processes that will shape the future of automotive manufacturing.

Lighter Materials: Paving the Way for Efficiency

The pursuit of improved fuel efficiency and reduced emissions has led to a significant shift towards lighter materials in automotive manufacturing. Gone are the days when steel reigned supreme as the primary material in car manufacturing. Automakers are now exploring alternatives, driven by the pursuit of improved fuel efficiency and reduced emissions. Why? Well, steel, although strong, comes with a hefty weight and cost that just won’t do anymore.

Aluminium, carbon fibre, and composites are increasingly being employed to achieve lighter and more efficient vehicles.

The adoption of lighter materials in the Indian automotive industry is a positive trend that is helping to improve the environmental and safety performance of Indian cars. However, there are some challenges that need to be addressed, such as the cost and availability of lighter materials.

Aluminium

Let’s start with aluminium, a lightweight material that has become a viable substitute for steel. Besides its weight advantage, aluminium boasts enhanced fuel efficiency and superior resistance to corrosion. This means that automotive components made of aluminium can not only help vehicles go the extra mile but also stand the test of time. However, it’s important to note that aluminium does come at a higher price compared to steel, influencing its overall cost-effectiveness.

Carbon Fibre

It represents the epitome of lightweight and high-strength materials, but its production cost has historically limited its use in mass-produced vehicles. The good news is that advancements in production methods are making carbon fibre more accessible to the automotive industry. With its exceptional strength and lightweight characteristics, carbon fibre is poised to revolutionise the design and performance of future vehicles. Get ready for cars that are not only sleek and stylish but also deliver unparalleled power and efficiency.

Composites

Composites, the dynamic blend of materials like fibreglass, carbon fibre, and resin, are taking the automotive world by storm. These materials offer impressive strength-to-weight ratios, making them perfect for moulding into complex shapes. Manufacturers now have the freedom to unleash their creativity and push the boundaries of design. From aerodynamic exteriors to innovative interiors, composites offer endless possibilities. It’s time to bid farewell to conventional constraints and embrace the future of automotive innovation.

As we strive for a greener future, these advancements in materials and processes bring us closer to achieving our goals of reducing emissions and minimising our environmental impact.

Efficient Manufacturing Processes: Pioneering Innovation

In addition to the adoption of lighter materials, automakers are embracing more efficient manufacturing processes to streamline production and enhance productivity. Let’s dive into three groundbreaking techniques leading the way: Automation, 3D Printing, and Additive Manufacturing:

Automation

“The use of automation in the automotive industry is expected to increase by 20% in the next 5 years in India”.

Automation involves the utilisation of robots and other machines to perform tasks that were once exclusively carried out by humans. By automating various stages of the manufacturing process, efficiency is significantly improved, while costs are reduced. Automated systems ensure consistency, precision, and speed, resulting in higher-quality products and increased productivity.

3D Printing

It is also known as additive manufacturing, and has gained significant traction in the automotive industry. This technology utilises computer-aided design (CAD) models to create three-dimensional objects layer by layer. 3D printing is instrumental in producing prototypes, moulds, and even final parts. Its flexibility and precision make it an invaluable tool for automotive manufacturers, enabling rapid prototyping, customization, and the production of complex geometries.

Additive Manufacturing

It is a subset of 3D printing, enabling the creation of intricate parts that would be challenging or impossible to manufacture using traditional methods. This technique builds objects layer by layer, allowing designers to push the boundaries of what is achievable in terms of part complexity and customization. Additive manufacturing offers the automotive industry the ability to produce lightweight, optimised components with reduced material waste.

Sustainable Materials: Nurturing Environmental Responsibility

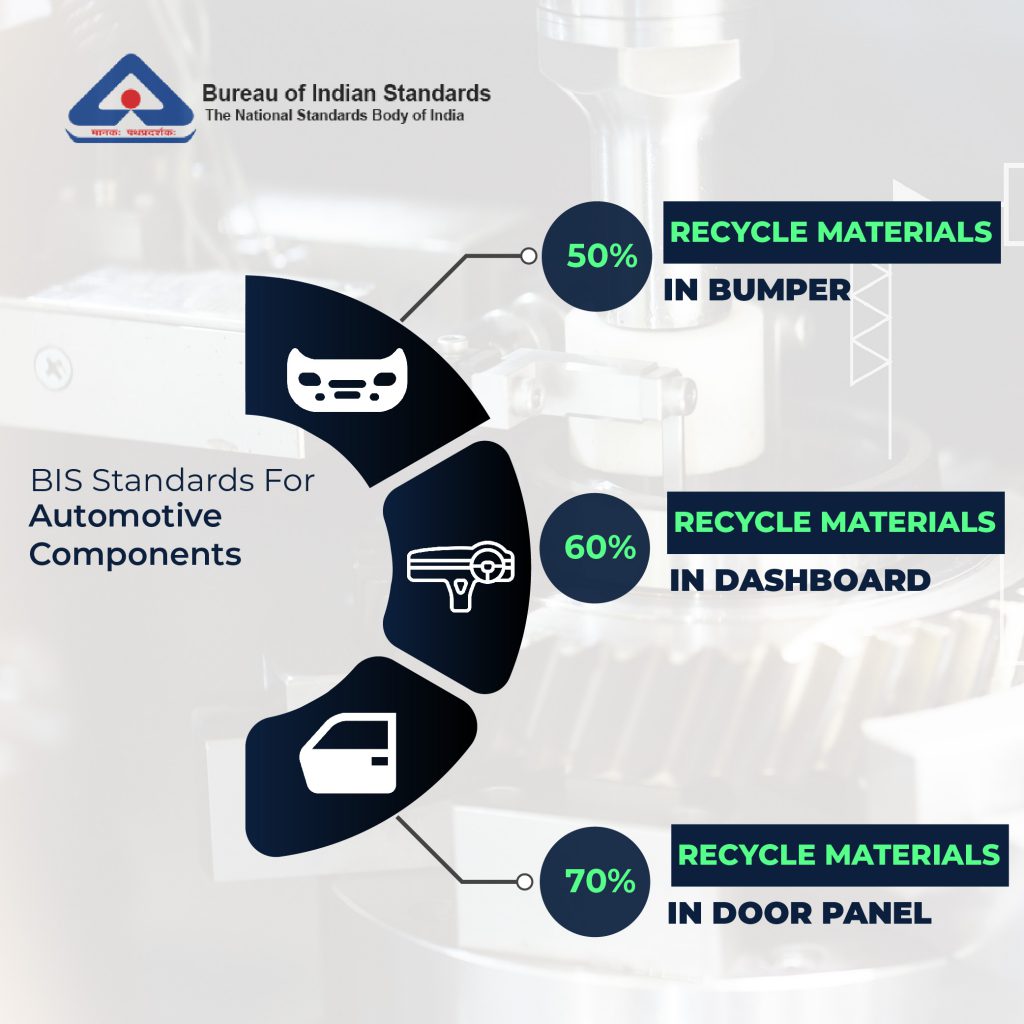

“The Bureau of Indian Standards (BIS) standards are helping to promote the use of recycled materials in the automotive industry and to reduce the environmental impact of the industry. These standards require that a certain percentage of recycled content be used in certain components, such as bumpers, dashboards, and door panels.”

The BIS standards for recycled materials in automotive components are as follows:

Bumpers: 50% recycled content

Dashboards: 60% recycled content

Door panels: 70% recycled content

Increasing consumer demand for sustainable products and stringent government regulations are driving the automotive industry to explore more environmentally friendly materials. Several promising options are emerging as viable alternatives to conventional materials.

Bio-Based Plastics

It is derived from renewable resources like corn, sugarcane, and soybeans, which are particularly noteworthy. These plastics exhibit similar strength and durability to traditional counterparts but offer the added benefits of biodegradability and compostability. By utilising bio-based plastics, automakers can significantly reduce their environmental footprint. These plastics contribute to a more circular economy, where resources are utilised responsibly and waste is minimised.

The utilisation of recycled materials presents another avenue for sustainability in automotive manufacturing. By repurposing and incorporating recycled materials into the production process, waste generation is reduced, and valuable resources are conserved. Recycled plastics, metals, and fibres can be used in various automotive components, such as interior trims, underbody panels, and structural reinforcements.

The Road Ahead: Trends and Implications

The future of automotive manufacturing is poised for significant advancements driven by evolving materials and processes. The following trends are set to shape the industry’s landscape:

- Increasing use of lighter materials, including aluminium, carbon fibre, and composites, to achieve enhanced fuel efficiency, performance, and safety. Lighter vehicles contribute to reduced emissions and improved handling, while maintaining structural integrity.

- Continued integration of efficient manufacturing processes, such as automation, 3D printing, and additive manufacturing, for improved productivity and cost-effectiveness. These technologies enable faster prototyping, customization, and the production of complex components, leading to reduced lead times and increased manufacturing flexibility.

- Growing adoption of sustainable materials, like bio-based plastics and recycled materials, to meet consumer expectations and comply with regulatory requirements. Automakers are recognizing the importance of environmental responsibility and are actively seeking ways to reduce their carbon footprint and waste generation throughout the manufacturing process.

Conclusion

In conclusion, the automotive manufacturing industry is at the forefront of a remarkable transformation. Advancements in materials and processes are paving the way for lighter, more efficient, and environmentally sustainable vehicles. From the adoption of aluminium, carbon fibre, and composites to the integration of automation, 3D printing, and additive manufacturing, the industry is embracing innovation to improve fuel efficiency, productivity, and environmental responsibility.

By staying at the forefront of these trends, automakers can deliver vehicles that meet the evolving demands of consumers, regulatory requirements, and contribute to a greener future. The road ahead is filled with endless possibilities, and the future of automotive manufacturing looks brighter than ever.

Leave a Reply