Electric vehicles (EVs) are gaining popularity worldwide, and as the demand for these vehicles increases, there is a greater need for efficient and reliable electric motors. When it comes to EV motors, the below three main types are widely used: Permanent Magnet Synchronous Motors (PMSMs), Induction Motors, and Brushless DC Motors.

Each type has its own advantages and disadvantages, making it important for an Automobile company to choose the right motor for their EV vehicles.

EV Motors & Their Types

Let’s start by understanding the basic functionality of these motor types and how they drive the EV industry. Essentially, an electric motor is a device that converts electrical energy into mechanical energy, propelling the vehicle forward. All motors consist of a rotor, a stator, and a set of windings. As electric current flows through the windings, a magnetic field is created. This magnetic field interacts with the magnetic field of the stator, resulting in the rotation of the rotor, which powers the electric vehicle.

Let’s delve into the different types of EV motors:

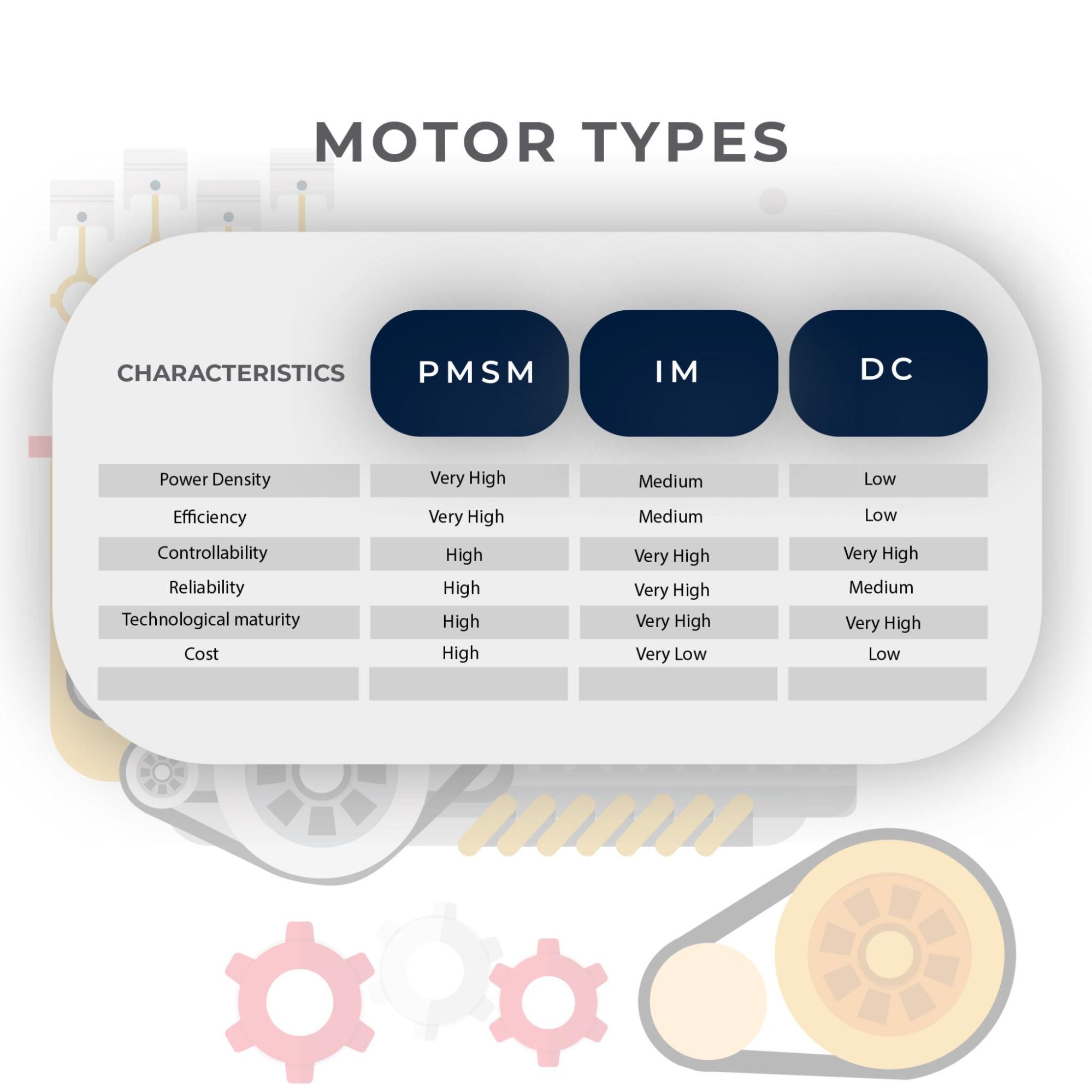

Permanent Magnet Synchronous Motors (PMSMs):

PMSMs are the most commonly used motors in EVs. They are known for their efficiency, reliability, and long lifespan. PMSMs generate a rotating magnetic field using a permanent magnet, which interacts with the stator coils to produce the electric current that powers the motor. PMSMs strike an optimal balance between efficiency, reliability, and cost-effectiveness. They are also relatively easy to manufacture, contributing to lower overall costs.

Induction Motors:

Induction motors are a more budget-friendly option compared to PMSMs, but they tend to be less efficient and have a shorter lifespan. These motors create a rotating magnetic field through the stator coils, inducing a current in the rotor. The resulting current generates a magnetic field that interacts with the stator field to produce torque. Induction motors are suitable for budget-conscious EV buyers as they offer adequate performance for most driving conditions, though they may not be as efficient as PMSMs.

Brushless DC Motors:

Brushless DC motors are the most efficient type of motor available but also the most expensive. They utilise a DC motor with a controller to generate a rotating magnetic field that interacts with the stator coils, producing the electric current needed to power the motor. These motors are primarily used in high-performance EVs such as Tesla’s Model S Plaid. Despite being more costly, brushless DC motors offer superior efficiency compared to induction motors.

Key Factors in Choosing Motors for EV Segment Vehicles

Now, let’s explore the steps involved in the motor selection process, highlighting the key factors that automobile companies take into account.

The motor selection process involves a series of steps that enable automobile companies to make informed decisions. Let’s examine the factors, which contribute to achieving the desired outcomes for EVs.

Cost Considerations:

Cost is a significant factor in the motor selection process. Automobile companies aim to strike a balance between performance requirements and affordability to ensure their EVs are competitive in the market. Factors such as motor manufacturing costs, economies of scale, and potential long-term savings in maintenance and operating expenses are carefully considered. By selecting a cost-effective motor, automobile companies enhance the overall viability and market competitiveness of their EVs.

Battery Compatibility:

Selecting a motor that is compatible with the EV’s battery system is crucial for seamless integration and efficient power transfer. Factors such as voltage, current, and charging capabilities are taken into account to ensure proper alignment between the motor and battery. Compatibility ensures optimal performance, longevity, and efficient utilization of the battery’s capabilities.

Power Rating:

Determine the power requirements of your application to select a motor that can handle the workload effectively. Consider factors such as load demands, duty cycle, and potential future expansions or changes that may impact power requirements.

Torque Rating:

Assess the torque requirements of your application to ensure the motor can provide sufficient force to move the load. Consider factors such as load characteristics, starting torque requirements, and potential variations in torque during operation.

Efficiency:

Choose a motor with higher efficiency to minimise energy consumption and reduce operating costs. Look for motors that adhere to recognized efficiency standards such as NEMA Premium or IE3.

Performance:

Evaluate various performance factors such as speed, acceleration capabilities, precision control requirements, and noise level. Tailor your motor selection to meet the specific demands of your application effectively.

Warranty and Customer Support:

Opt for a motor from a reputable manufacturer that offers a warranty and good customer support. A longer warranty period provides peace of mind and protects your investment.

By considering these factors, Automobile companies select electric motors, ensuring optimal performance, longevity, and a successful outcome for your motor-driven EV.

The Future of EV Motor Manufacturing

As the demand for EVs continues to rise, the development of more efficient and reliable electric motors becomes paramount. The EV motor manufacturing industry is experiencing rapid growth, with numerous companies striving to develop innovative motor technologies.

Some key trends in EV motor manufacturing include:

Embracing Lighter and Stronger Materials: Enhancing Efficiency and Reducing Vehicle Weight

One of the prominent trends in EV motor manufacturing is the adoption of lighter and stronger materials. By incorporating advanced materials such as high-strength alloys, carbon fibre composites, and lightweight polymers, manufacturers can significantly reduce the overall weight of EV motors. This reduction in weight has a twofold benefit: it enhances the efficiency of the motor and contributes to the overall weight reduction of the vehicle.

Lighter EV motors require less energy to propel the vehicle, resulting in improved energy efficiency and extended driving range. Additionally, reduced vehicle weight translates to lower energy consumption, allowing EVs to maximise their battery capacity and minimise charging frequency. By embracing lighter and stronger materials, manufacturers are pushing the boundaries of efficiency and redefining the possibilities of electric mobility.

Adopting More Efficient Manufacturing Processes: Driving Down Costs and Enhancing Production Efficiency

In the quest for more affordable and accessible EV motors, manufacturers are investing in the development and implementation of more efficient manufacturing processes. Advanced automation technologies, such as robotics and machine learning, are revolutionising the production lines, streamlining operations, and reducing manufacturing costs.

By automating repetitive tasks and optimising production workflows, manufacturers can achieve higher levels of precision, consistency, and productivity. This, in turn, contributes to cost reduction, making EV motors more affordable for consumers. Furthermore, efficient manufacturing processes allow for greater scalability and faster production, enabling manufacturers to meet the growing demand for EV motors in a timely manner.

Developing New Motor Designs: Enhancing Performance and Efficiency

The pursuit of better performance and efficiency is at the core of EV motor development. Manufacturers are continuously exploring new motor designs and configurations to unlock the full potential of electric propulsion. These innovative designs focus on maximising power output, improving torque characteristics, and minimising energy losses during operation.

For instance, some manufacturers are exploring advanced magnet technologies, such as rare-earth magnets and magnetised laminated cores, to enhance the magnetic field strength and overall motor efficiency. Others are integrating advanced control systems and algorithms to optimise motor performance in real-time, allowing for dynamic adjustments based on driving conditions.

Additionally, the development of compact and integrated motor designs is gaining traction. By integrating multiple components and subsystems into a single unit, manufacturers can reduce the size, weight, and complexity of EV motors while maintaining or even enhancing their performance and efficiency.

These developments in motor design hold tremendous potential for the future of electric vehicles. As EV motors become more sophisticated, we can expect increased power, improved acceleration, and enhanced overall driving experience, all while maximising energy efficiency and range.

Conclusion

In conclusion, the evolution of electric vehicle motor technologies is shaped by the adoption of lighter and stronger materials, the implementation of more efficient manufacturing processes, and the development of new motor designs.

These trends not only enhance the efficiency and performance of EV motors but also contribute to the affordability and accessibility of electric vehicles for a wider audience. As the electric revolution accelerates, we can look forward to even more groundbreaking innovations that will propel us towards a cleaner, greener, and more sustainable future of transportation.

Leave a Reply